charpy impact test methodology|charpy impact test diagram : fabrication In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. WEB18 de set. de 2023 · Martina Oliveira, produtora de conteúdo no OnlyFans, foi cancelada nas redes sociais por publicar um vídeo que aborda um rapaz, num shopping de Porto .

{plog:ftitle_list}

Resultado da 23 de jun. de 2023 · Após derrota na Libertadores, Renato Gaúcho é demitido do Flamengo. Conteúdos, Notícias e Tudo sobre Renato Gaúcho. .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .

Unlock the essentials of the Izod / Charpy Impact Test with our in-depth guide. Learn about its definition, calculation methods, and why it’s crucial for material testing, aligning with ASTM standards, including ASTM D256 and .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction . Charpy Impact Testing, also known as the “Charpy V-notch test,” is a standardized test method used to determine the impact toughness of materials, particularly metals. It .

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .The standard test method for the Charpy impact resistance of FRP composites can be found in ASTM D6110 [51] and EN ISO 179 [52]. This test method can be performed in a fully automated way with a small technical effort, and the specimen can be inexpensively machined. However, the specimen is a short and thick beam, which may not be .

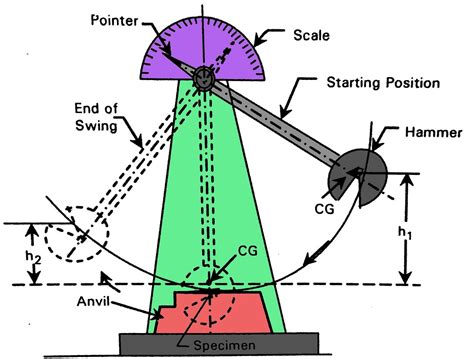

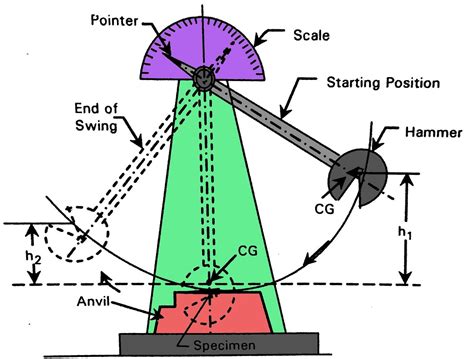

useful in the development of a standardized test method for Charpy impact testing of cementitious composites. The Charpy Test The Charpy impact test relies on the potential energy of a weighted pendulum as shown in Fig. 1. The pendulum is raised to some initial height h i, which is measured from the center of mass to the datum. A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force sensors on the striker's edge, allowing scientists to record the . 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or . The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus This test determines the amount of .

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . 3 A Novel Method for Accurate SoC Estimation in LiFePO4 Batteries.

charpy impact testing procedure

Charpy testing is a method for determining the relative impact strength of metals. It is also known as Charpy V notch test. . The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for . Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact test where a weighted pendulum hammer is released from a specified height and strikes the part. A Charpy impact testing apparatus, a .

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .

The four most common impact-test procedures in use around the world are probably ISO 148 “Steel— Charpy impact test V-notch ,” ASTM E 23 “Standard Test Methods for Notched Bar Impact Testing of Metallic Materials,” EN 10045 “Charpy Impact Test for Metallic Materials,” and JIS Z2242 “Method for Impact Test for Metallic Materials.” ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .Methods for Notched Bar Impact Testing of Metallic Materials (E 23) has over the years been to standardize and control the variables associated with impact testing. This report looks at the history of impact testing, with emphasis on the key advances in understanding and application of the impact test, as reflected in the evolution of the test

The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good Quality Control (QC) method, and is globally accepted. . Schematic of a Typical Charpy Impact .CHARPY IMPACT TESTING IZOD IMPACT TESTING Tested Materials Plastics Plastics Types of Notches (0.25mm) Preferred V-notch V-notch . ASTM test method does not use a square at the end of the unit. DATA SHEET CONVERSION FACTOR Impact ISO Unit ASTM Unit ISO to ASTM ASTM to ISO Charpy kJ/m² ft-lb/in * by 0.476 * by 2.1 Charpy impact strength is significantly affected by the interfacial bond strength, by extension the interlaminar shear strength (ILSS), which is controlled by fiber surface treatments and manufacturing processes [12], [13], [19].The fracture initiation energy during Charpy impact testing increases with increasing ILSS, and displays a minimum when a critical value of ILSS .

Int J of Pressure Vessels and Piping, 78, 463-470. Wallin, K., Nevasmaa, P., Planman, T., Valo, M., 2002. Evolution of the Charpy-V Test from a Quality Control Test to a Materials Evaluation Tool for structural Integrity Assessment. In: From Charpy to Present Impact Testing, ESIS Publication 30, François, D. and PineauCharpy Impact Test: In this method, a test specimen is held at one end and struck on the opposite end with a pendulum hammer. The amount of energy absorbed by the specimen during fracture is measured. Izod Impact Test: This test method is similar to the Charpy impact test, but the specimen is held vertically, and the hammer strikes the specimen on the same side as . In 1922, the American Society for Testing and Materials (ASTM) organized a symposium on impact testing, and 10 years later, the first ASTM E23-33T “Tentative Method of Impact Testing of Metallic Materials” was finally released, specifying the use of a pendulum, both Charpy and Izod, a V-notch specimen, and a measurement system.Scope- This standard specifies the Charpy impact ( V-notch ) method for determining impact strength of the metallic material. 2. Principle - This test consists in breaking by one blow from a swinging pendulum, under conditions defined hereafter, a test piece V-notched in the middle and resting on two supports.

The Charpy Impact Test, also called as the Charpy V-notch test, is a standardized assessment designed for high strain rate testing. This method quantifies the energy absorbed by a material upon fracture, serving as an indicator of the material's notch toughness.

charpy impact testing methods

3m scuff it

Fortunately, the cheap and simple specimen design and test methodology for Charpy testing means that there is a large amount of Charpy data available, and more is produced every year. Where Charpy tests exceed the specification requirements for impact toughness, it can be confidently assumed that the material is unlikely to experience problems .

Metallic materials — Charpy pendulum impact test — Part 1: Test method 1 Scope This part of ISO 148 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 does not cover instrumented impact testing, which is specified in ISO 14556.

3m scuff pad

charpy impact test sample

23 de fev. de 2024 · EarthsoundsDOCUMENTARY. This landmark series uses cutting-edge audio technology and filming techniques to reveal our planet in a stunning new way through breathtaking, never-before .

charpy impact test methodology|charpy impact test diagram